Rigid Welding’s detailed approach to pressure vessel and tank services starts with a complete needs assessment. We can start from scratch or assess what you’ve got in place. From there, we make recommendations based on your needs and budget. We can draft, design, engineer, inspect and test as needed. We back all of our work with a 100% customer satisfaction guarantee.

Rigid Welding’s detailed approach to pressure vessel and tank services starts with a complete needs assessment. We can start from scratch or assess what you’ve got in place. From there, we make recommendations based on your needs and budget. We can draft, design, engineer, inspect and test as needed. We back all of our work with a 100% customer satisfaction guarantee.

Whatever your process vessel and reactor needs are, we will deliver the results and solutions you need in less time. Whether you need stand-alone or modularized vessels, we design and build them exactly as you need them.

Our process vessel and reactor services include:

Stand-alone vessels

From storage tanks to silos, we have the experience and capabilities to manufacture horizontal or vertical products using the same stringent manufacturing standards as our pressure vessels.

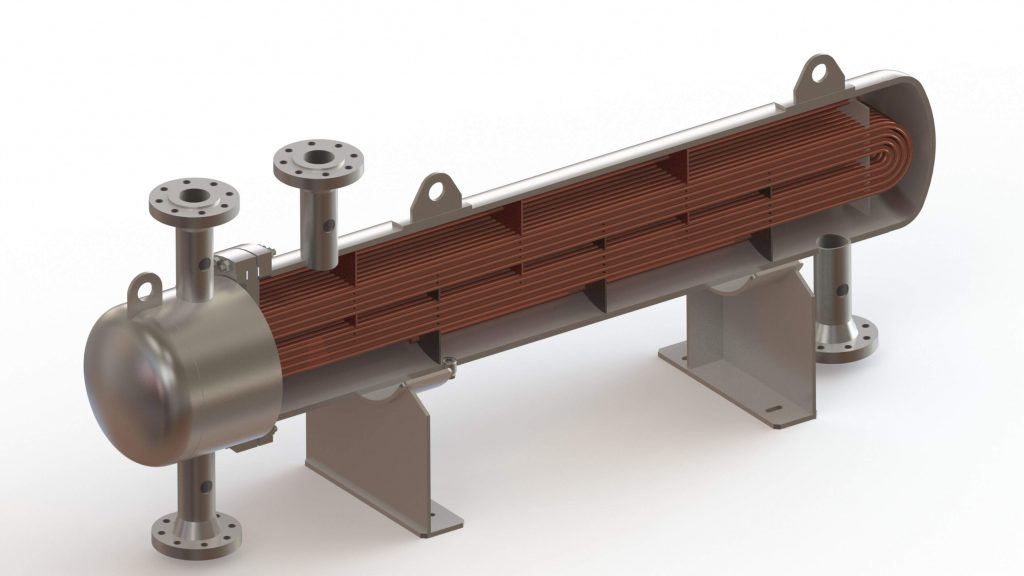

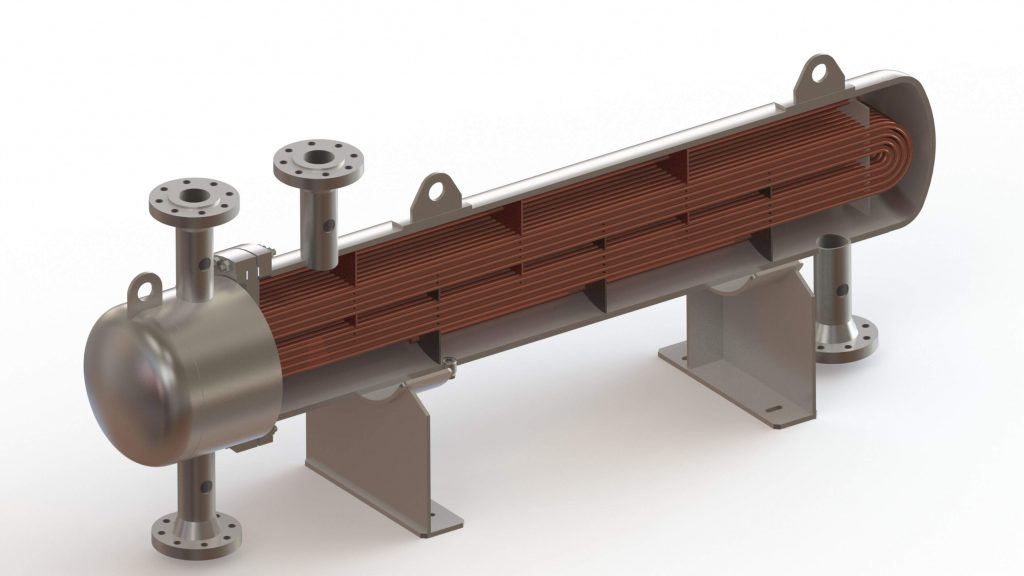

We manufacture all of our heat exchangers to suit our customers’ needs. Rigid Welding has the expertise and experience required to fabricate, design, and engineer shell and tube heat exchangers. We back all of our work with a 100% customer satisfaction guarantee.

We do more than just process vessels and reactors, storage tanks and vessels, pressure vessels and tanks, silos, and heat exchangers.

Our other vessel solutions and services include:

Rigid Welding offers a variety of inspection services. Let us help you ensure that your vessels and tanks are safe, functioning efficiently, and up to the job!

Our inspection services include:

Medical gas piping

NEED OUR SERVICES?