Your project is unique, and so are your needs. We work with you to create a custom metal fabrication design solution. You’ll work directly with one of our professionals through the design phase. We can design it for you based on your vision, or we can provide a quote and recommendations on existing drawings.

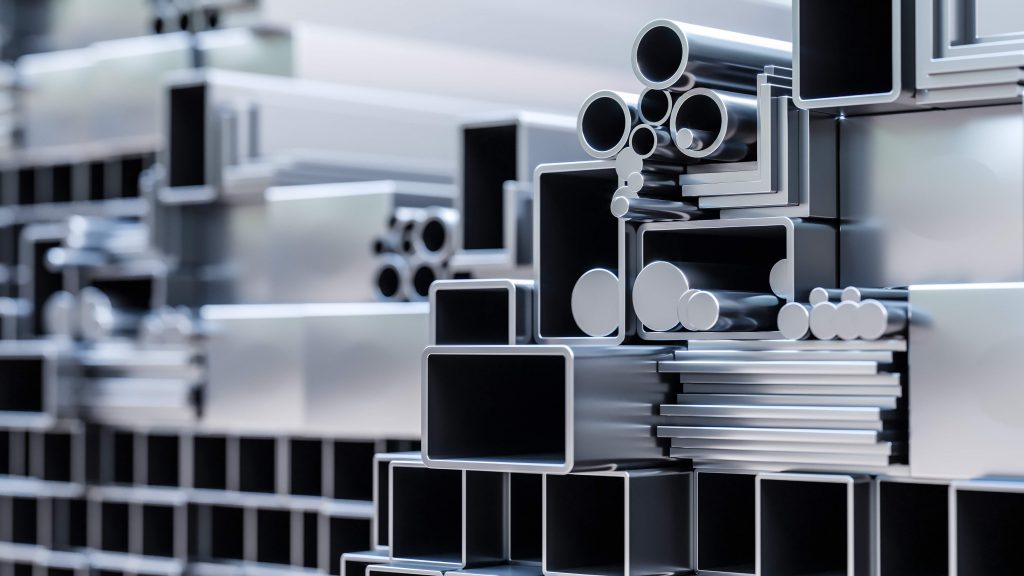

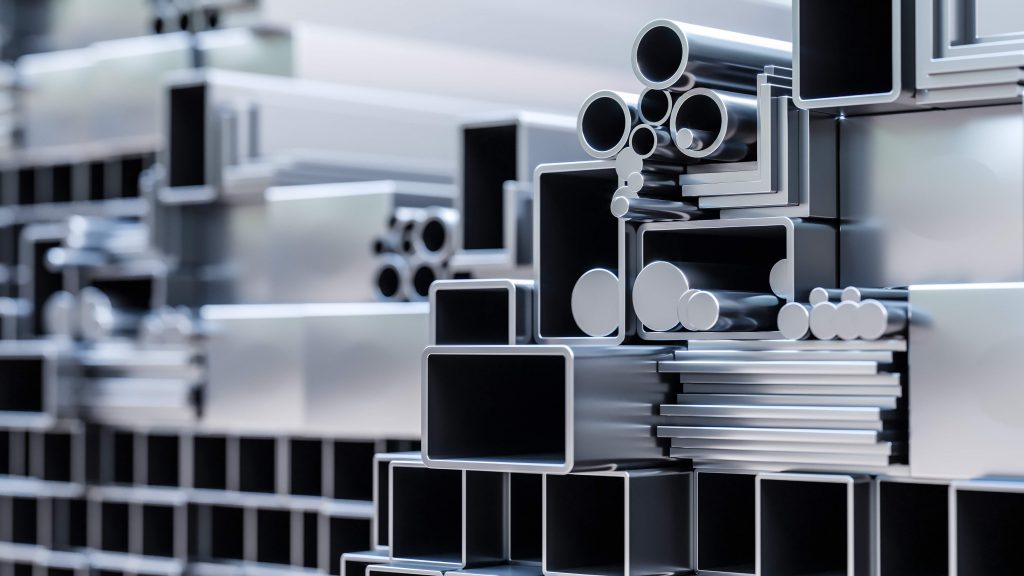

No matter your specifications or requirements for materials usage, Rigid Welding can help. We work with a variety of metals, including:

Can’t see what you need? Give us a call. We can develop a custom solution for you.

Finishing and assembly are integral to any project. We offer finishing options such as surface prep or grinding to help you facilitate control over the finished project and manage project costs and timing.

Our finishing services include:

NEED OUR SERVICES?